Things about Roar Solutions

Things about Roar Solutions

Blog Article

9 Simple Techniques For Roar Solutions

Table of ContentsUnknown Facts About Roar SolutionsRoar Solutions for BeginnersSome Of Roar SolutionsNot known Details About Roar Solutions

The tools register is a detailed database of tools documents that includes a minimum collection of areas to identify each item's location, technological parameters, Ex category, age, and ecological information. This details is crucial for monitoring and handling the equipment effectively within unsafe areas. In contrast, for routine or RBI sampling evaluations, the quality will certainly be a mix of In-depth and Close assessments. The ratio of Detailed to Shut examinations will certainly be identified by the Equipment Threat, which is examined based upon ignition danger (the possibility of a source of ignition versus the likelihood of a flammable environment )and the hazardous location category( Zone 0, 1, or 2). This variant will additionally affect the resourcing needs for work prep work. Once Lots are specified, you can create sampling plans based upon the example dimension of each Whole lot, which describes the number of random tools things to be evaluated. To establish the called for example dimension, two aspects need to be assessed: the dimension of the Whole lot and the group of inspection, which suggests the degree of initiative that need to be used( lowered, regular, or raised )to the examination of the Lot. By combining the category of inspection with the Lot size, you can after that develop the suitable rejection criteria for an example, suggesting the allowed number of faulty products located within that example. For more details on this process, please refer to the Power Institute Guidelines. The IEC 60079 common suggests that the maximum period in between assessments must not surpass 3 years. EEHA evaluations will additionally be conducted beyond RBI projects as part of scheduled upkeep and devices overhauls or repair work. These evaluations can be credited towards the RBI example sizes within the affected Whole lots. EEHA assessments are conducted to identify mistakes in electric equipment. A heavy scoring system is necessary, as a solitary item of devices may have multiple faults, each with differing degrees of ignition risk. If the mixed score of both assessments is less than two times the mistake rating, the Great deal is deemed acceptable. If the Whole lot is still considered undesirable, it should undertake a complete examination or justification, which might activate more stringent evaluation methods. Accepted Whole lot: The root causes of any kind of faults are determined. If a typical failure mode is located, added equipment may call for maintenance. Mistakes are identified by severity( Security, Honesty, House cleaning ), guaranteeing that immediate issues are assessed and attended to immediately to mitigate any type of effect on security or procedures. The EEHA data source should track and tape the lifecycle of mistakes in addition to the rehabilitative activities taken. Applying a durable Risk-Based Inspection( RBI )strategy is critical for ensuring compliance and security in taking care of Electric Devices in Hazardous Locations( EEHA). Automated Mistake Rating and Lifecycle Monitoring: Effortlessly manage faults and track their lifecycle to enhance assessment precision. The intro of this assistance for risk-based evaluation even more enhances Inspectivity's setting as a best-in-class remedy for regulatory conformity, along with for any asset-centric evaluation use case. If you have an interest in discovering more, we invite you to ask for a presentation and find how our service can transform your EEHA management processes.

With over ten years of combined Ex-spouse experience (IECEx/ATEX, EEHA), Saipex started to promote the relevance of skills of all personnel entailed in the Hazardous Area field in 2019. In 2021, our collaboration with IndEx and Tech Skill International (TSI) marked a landmark in the Saipex road to continue Ex-spouse renovation.

The Roar Solutions Ideas

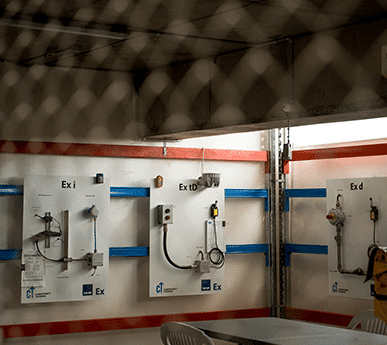

In regards to eruptive risk, a hazardous area is an environment in which an eruptive atmosphere is present (or may be anticipated to be existing) in quantities that need unique preventative measures for the building, setup and usage of tools. In this short article we explore the difficulties dealt with in the work environment, the risk control procedures, and the required expertises to work securely.

(https://www.startus.cc/company/roar-solutions)

It is a consequence of modern life that we manufacture, store or handle a range of gases or liquids that are deemed flammable, and a series of dusts that are considered combustible. electrical refresher course. These compounds can, in certain conditions, form eruptive ambiences and these can have major and tragic repercussions. A lot of us know with the fire triangle get rid of any kind of among the three components and the fire can not take place, yet what does this mean in the context of hazardous locations? When breaking this down into its most basic terms it is essentially: a mix of a particular amount of release or leak of a specific material or product, mixing with ambient oxygen, and the existence of a source of ignition.

This is after that confirmed with assessment and screening and is protected throughout the life of the setup by employing the correct maintenance methods, supplemented by regular examination. When all these procedures are taken, they should additionally be recorded. The confirmation file consists of information such as the dangerous area classification drawing, manufacturers' documentation, devices certification, layout drawings and calculations, assessment records, and records of an individual's competency and continuing professional growth (CPD), such as through ECA's eCOMS software.

Little Known Questions About Roar Solutions.

It is important that trainees recognize and have a thorough expertise regarding what exactly constitutes an unsafe location. The student must likewise know why training is essential before attempting to handle job or defining devices into an unsafe location. These areas are likewise known as identified locations and are defined as areas which have a high probability of an explosion due to the feasible existence of flammable gases, vapors, dusts and so on.

Industries that contain hazardous locations are currently requiring that electrical employees that are Homepage specifying or operating in these locations ought to have an unsafe area qualification that deems them experienced. Jobs in these markets are really fulfilling so you need to be prepared. To meet this demand for the industry, across the country acknowledged training in Certification IV in Unsafe location Electrical and EEHA training on the development of proficient experts.

Roar Solutions Can Be Fun For Everyone

Technology Skills Australia is a Registered Training Company offering you with the most budget friendly and quickest method obtaining your qualification - high voltage courses. Our instructors are sector qualified and have numerous years of process experience. Our courses have aided thousands of people from company managers to daily workers in getting a solid hold on this not so complex however high risk training

The training likewise includes determining the hazardous locations, resources of explosion and the homes of harmful materials together with the responsibilities and features of all events, guidelines, systems, criteria and technique codes attached to hazardous areas. We offer instrumentation and unsafe area remedies that are in compliance to latest AS/NZS and international industry criteria.

Report this page